Manufacturing Process

For the effective and bulk production of Steel Pipes & Tubes, we have developed a sophisticated manufacturing unit. Equipped with high-end machines and equipment, we are able to provide our clients with a superior and defect free range of pipes and tubes. The manufacturing process of Galvanized & Steel Pipes & Tubes is mentioned below:

• Depending on end applications, Hot-rolled or

cold-rolled close annealed strips are used to manufacture

tubes

• Manufacturing starts in a separate

preparatory section where the initial raw materials are slit

into required tube widths

• These are processed through the modern,

strip-pickling plant to remove all surface defects before

feeding into the tube mills

• Bright finish tubes, high tensile strength

tubes, sectional tubes and others are precision engineered in

the mills with its own design specialties

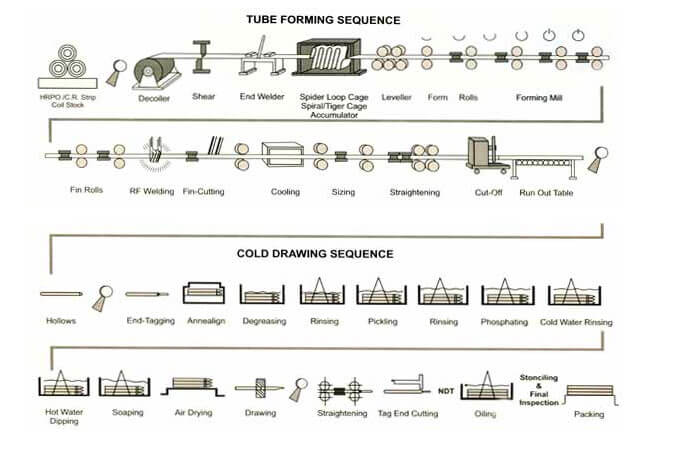

The tubes are welded in the tube mill by high frequency solid state welding process, which is as follows:

• Induction coil encircles the strip formed

into a tubular section by its progressive movement through sets

of specially designed rolls

• The butted ends of the tube are welded

without any filler by electric resistance welding.

• This results in a close and tight

weld-joint, free from inclusions and other defects, maintaining

the parent material integrity

• The final rolls towards the end of the tube

mill ensure straightening and sizing of tubes

• The sectional tube of rectangular or square

sections may be achieved through specially designed, contoured

rolls

• Cold saw installed at the tube mill cuts the

tube with close tolerance giving burr free & dimple free tube

ends

• The ERW precision tubes are collected in the

turn-table

These tubes have to undergo additional processes like annealing, pressure testing, eddy current testing, straightening or further cutting. This designs the tubes as per their application specific requirement specified by our clients.

CDW Precision Tubes

We manufacture CDW precision tubes of close tolerances that are used for special applications including modern draw benches. CDW tubes are manufactured from tube mills through a plug and die combination, mounted on the draw bench. The end tagged and annealed tubes are produced through machined die. This controls the outside diameter of the tubes and for controlling the inside diameter, it passes over a plug.

Moreover, high precision bobbin tubes, front fork tubes, cylinder bore tubes and others are processed by the downstream facilities available at our manufacturing plant. This makes the tubes applicable for various industries like auto industry, shock absorber industry or for pressure applications as in boilers.