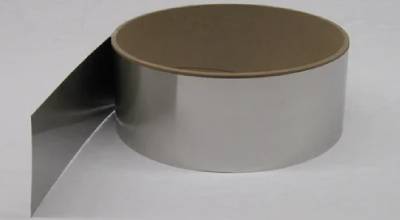

Hastelloy C276 Foils & Strips

Hastelloy C276 Strips & Foils, ASTM B575 Hastelloy C276 Foil Supplier, UNS N10276 Strips Stockist in India.

Hastelloy Alloy C276 Foils, ASTM B622 Hastelloy C276 Strips Exporter, WNR 2.4819 Hastelloy C276 Strip Manufacturer.

AB Steel is a trusted manufacturer, supplier, and exporter of Hastelloy C276 Foils in India and globally. With extensive experience in the production of high-quality nickel alloy products, we ensure precision production and strict quality control at each step. Hastelloy C276 is a nickel-molybdenum-chromium alloy that offers outstanding resistance to severe oxidizing, and reducing chemicals, rendering it extremely suitable for severe chemical environments. These foils find extensive usage in chemical processing, marine, pollution control, pulp and paper and waste treatment industries and provide consistent performance under severe conditions. This high resistance to corrosion, strong mechanical properties, and durability of Hastelloy C276 foils make them the top choice for important applications that need materials that last a long time and require minimum maintenance.

Hastelloy C276 Foils & Strips are manufactured as per ASTM B575 and ASME SB575 standards. Available in UNS N10276 and W.Nr. 2.4819 grades, offering excellent resistance to strong oxidizers and corrosion. Widely used in chemical processing, pollution control, and marine engineering applications.

Hastelloy C276 Foils & Strips

Hastelloy 2mm Foils & Strips

Hastelloy 3mm Foils & Strips

Hastelloy C276 foils, and strips are high-grade nickel alloys recognized for outstanding resistance in hostile conditions. The materials have high nickel content, with the addition of molybdenum, chromium, and trace amounts of tungsten. It is resistant to pitting, crevice corrosion, and stress corrosion cracking. The alloy is suitable for both oxidizing and reducing conditions, and is resistant to mechanical strength loss at elevated temperatures. Its resistance guarantees a long operational life and less maintenance requirement, making it suitable for chemical processing, marine and other corrosive environments. Hastelloy C276 is strong, resistant to rust, and can handle high temperatures, making it a dependable choice for tough industrial systems where regular materials would break down. These foils and strips are safe, efficient and long lasting, a sensible choice for the demanding applications that need low-maintenance, high performance materials.

Hastelloy C276 foils are available in thicknesses ranging from 0.025 mm to 0.1 mm. They come in widths up to 300 mm and can be supplied in rolls or as cut sheets to meet project requirements. Surface finishes include bright annealed, cold-rolled, and polished, allowing flexibility in applications where appearance or smoothness matters. Additionally, the foil can be used in heat exchangers, chemical tanks, precision equipment, and corrosion-resistant linings. Thickness, width, surface treatment and order size all affect price. Affordable prices for bulk orders frequently make it simpler for large scale projects to access materials effectively. In order to ensure minimal waste, and precise fit for certain industrial applications custom cutting, and finishing options are also offered.

Foils can be customized to meet exact requirements. Precision slitting, edge trimming, and surface coating are available to match client specifications. It can be cut to specific sizes to minimize material waste. Additional services include stamping, laser marking and packaging under cleanroom conditions, which are useful for sensitive industrial processes. Without sacrificing their strength or ability to withstand corrosion, foils can also be bent or curved to meet special patterns. Specialized coatings can enhance durability, or chemical resistance in specific applications. Manufacturers can more readily integrate Hastelloy C276 foils, into their systems, while maintaining safety, and quality standards using these options. Customers benefit from ready-to-use foils that reduce preparation time, and improve efficiency in production.

Prior to shipping, each coil is subjected to stringent quality inspection. To ensure consistent performance, this involves material verification, corrosion testing, and dimensional checks. Each batch is examined for mechanical properties, thickness accuracy, and surface flaws. We use sturdy wooden cases, sealed cartons, and protective wraps in the packaging when necessary to prevent damage during shipment. Customized packaging options are also offered for orders that are delicate, or valuable. Orders are shipped to Europe, the Middle East, Africa and Asia and they are delivered all throughout India. Whether for small projects, or large-scale industrial requirements, purchasers can easily acquire foils in great condition due to affordable pricing, attentive customer assistance, and dependable logistics that ensure on-time delivery.

Specification

| Specification | Details |

| Grade | Hastelloy C276 |

| UNS Number | N10276 |

| Werkstoff Nr. | 2.4819 |

| Standards | ASTM B575, ASME SB575 |

| Form | Foils, Strips, Coils, Rolls |

| Thickness Range | 0.025 mm – 3 mm (Foils & Strips) |

| Width | 10 mm – 1250 mm (custom on request) |

| Length | Coil Form / Cut-to-Length |

| Finish | Cold Rolled, 2B, Bright Annealed, BA, No.4, Mirror, Polished |

| Hardness | Soft, Quarter Hard, Half Hard, Full Hard, Spring Hard |

| Density | 8.89 g/cm³ |

| Melting Point | 1325 – 1370 °C |

| Corrosion Resistance | Excellent resistance to strong oxidizers, reducing agents, seawater, chloride stress cracking, and oxidizing salts |

| Applications | Chemical processing, Marine industry, Pollution control, Pulp & paper industry, Oil & gas, Power generation |

| Packaging | Wooden boxes, HDPE, Bubble Wrap, Coil Form |

Chemical Composition

| Element | Content (%) |

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Vanadium (V) | ≤ 0.35 |

| Carbon (C) | ≤ 0.01 |

| Silicon (Si) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.03 |

Mechanical Properties

| Property | Value |

| Density | 8.89 g/cm³ |

| Melting Point | 1325 – 1370 °C |

| Tensile Strength | 785 MPa (min) |

| Yield Strength (0.2%) | 355 MPa (min) |

| Elongation | 40% (min) |

| Hardness (Brinell) | 200 HB (approx.) |

Our Global network

Haryana, Sharjah, Doha, Kuwait City, Kolkata, Port-of-Spain, Abu Dhabi, Vung Tau, Nashik, Thane, Ho Chi Minh City, Navi Mumbai, Tehran, Algiers, Ulsan, Coimbatore, Bogota, Jamshedpur, Karachi, Faridabad, Atyrau, Noida, Edmonton, Calgary, Dubai, Cairo, Hyderabad, Hong Kong, Ahvaz, Pimpri-Chinchwad, London, Vadodara, Jakarta, Melbourne, Al Khobar, Aberdeen, New Delhi, Bhopal, Chandigarh, Moscow, Dammam, Mexico City, Kuala Lumpur, Petaling Jaya, New York, Chennai, Santiago, Milan, Los Angeles, Busan, Dallas, Geoje-si, Seoul, Jaipur, La Victoria, Istanbul, Mumbai, Gurgaon, Ankara, Madrid, Houston, Montreal, Singapore, Al Jubail, Pune, Ranchi, Colombo, Howrah, Baroda, Secunderabad, Ernakulam, Surat, Riyadh, Courbevoie, Lagos, Kanpur, Gimhae-si, Lahore, Thiruvananthapuram, Ahmedabad, Manama, Caracas, Muscat, Hanoi, Rio de Janeiro, Visakhapatnam, Bengaluru, Sydney, Bangkok, Jeddah, Chiyoda, Brisbane, Ludhiana, Granada, Rajkot, Toronto, Perth, Indore, Nagpur

Romania, India, Bahrain, Germany, Tibet, Italy, Nigeria, Jordan, Egypt, Argentina, Mongolia, Peru, Costa Rica, Spain, Brazil, Serbia, Portugal, Pakistan, Bangladesh, Thailand, Macau, Slovakia, Belgium, Austria, Lebanon, Ecuador, Sweden, Israel, South Korea, Ghana, Libya, Chile, Hong Kong, Chile, Japan, Poland, Nepal, Gambia, Algeria, Kenya, Trinidad & Tobago,Tunisia, Vietnam, Nigeria, Ukraine, Gabon, United Arab Emirates, South Africa, Estonia, United States, Taiwan, France, Qatar, Morocco, Angola, Bolivia, Bhutan, Switzerland, Bulgaria, Philippines, Sri Lanka, Puerto Rico, China, Canada, Netherlands, Saudi Arabia, United Kingdom, Hungary, Singapore, Ireland, Australia, New Zealand, Yemen, Denmark, Mexico, Lithuania, Czech Republic, Indonesia, Greece, Turkey, Zimbabwe, Croatia, Namibia, Norway, Russia, Iraq, Oman, Kazakhstan, Iran, Azerbaijan, Kuwait, Colombia, Afghanistan, Finland, Belarus, Malaysia, Venezuela