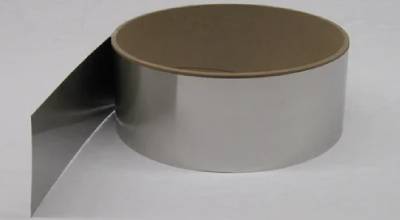

Inconel 625 Foils & Strips

Inconel 625 Strips & Foils, ASTM B443 Inconel 625 Foil Supplier, UNS N06625 Strips Stockist in India.

Inconel Alloy 625 Foils, ASTM B446 Inconel 625 Strips Exporter, WNR 2.4856 Inconel 625 Strip Manufacturer.

AB Steel is a trusted manufacturer, supplier, and exporter of Inconel 625 Foils in India and across international markets. known for its precision engineering and strict control over quality. It produces premium nickel alloy products that meet the highest industry levels. One of these products is Inconel 625, a nickel-chromium-molybdenum alloy known for its superior corrosion resistance, high tensile strength, and excellent oxidation resistance even under harsh conditions. It finds extensive use in marine engineering, chemical processing, aerospace, pollution control equipment, and high temperature industrial applications, making it a preferred choice for demanding environments.

Inconel 625 Foils & Strips are manufactured as per ASTM B443, AMS 5599, and AMS 5879 standards. Supplied in UNS N06625 and W.Nr. 2.4856 grades, offering superior strength and oxidation resistance. Widely used in marine, chemical, and aerospace industries for high-performance applications.

Inconel 625 Foils & Strips

Inconel 2mm Foils & Strips

Inconel 3mm Foils & Strips

Inconel 625 foils and strips contain nickel, chromium, molybdenum, and niobium to form an exceptionally high-performing alloy with excellent pitting, crevice corrosion, and chloride-induced stress corrosion cracking resistance. This blended content offers a protective cover that delivers durability, and long-term reliability in severely corrosive mediums. This alloy also exhibits an impressive level of fatigue strength which makes it resistant to repeated stress without losing its structural integrity. Their excellent weldability allows for effective fabrication without sacrificing the material's superior mechanical properties. Foils and strips of Inconel 625 work well over a broad range of temperatures from cryogenic temperatures to high temperatures of up to 982°C, being very versatile in many extreme requirements. TThe combination of strength, flexural toughness and corrosion resistance makes this alloy the best choice for industries requiring materials that can endure extreme thermal cycling and aggressive chemical exposure. Its ability to hold its performance under these conditions ensures consistent operation and long service life in critical applications.

We offer Inconel 625 Foils in rolls or custom-cut sheets, with thicknesses ranging from 0.025 mm to 0.1 mm and widths up to 300 mm. To meet certain operational requirements, the foils are available in various finishes, which include polished, bright annealed, and other surface treatments. The thickness, width, surface finishes and order volume are some of the variables that affect the price of Inconel 625 foil. For large-scale industrial orders, special bulk pricing is offered, ensuring affordable solutions for both low, and high volume requirements.

To satisfy exact customer requirements such as specific dimensions, surface treatments and unique packaging choices, we provide customized Inconel 625 Foils. These foils provide reliable performance in harsh environments and are often used in flexible expansion joints, marine heat exchangers, chemical processing liners and aircraft thermal insulation. They are perfect for both industrial, and cutting-edge technical applications, as it may be used in applications that call for lightweight materials without sacrificing strength, and resistance to corrosion. Each foil meets strict quality standards, ensuring reliable performance even under the most difficult conditions. Expert guidance is also provided in selecting the best foil for a specific set of operational requirements.

Each Inconel 625 foil is subjected to strict quality inspections by AB Steel, which include corrosion resistance testing, surface integrity checks and material verification. To avoid damage during transportation, foils are safely packed in wooden crates, strong carton boxes, or moisture-proof wrapping. With prompt customer service and affordable pricing, we ensure a smooth supply experience for customers globally by offering rapid and reliable delivery within India as well as in the international markets like Europe, the Middle East, Africa and Asia.

Specification

| Technical Data | Details |

| Product | Inconel 625 Foils & Strips |

| Standards | ASTM B443, ASTM B444, ASTM B446, AMS 5599 |

| UNS Number | N06625 |

| Werkstoff Nr. | 2.4856 |

| Equivalent Grades | Alloy 625, Nickel Alloy 625 |

| Forms Available | Foils, Strips, Sheets, Coils |

| Thickness Range | 0.02 mm to 3.0 mm |

| Width Range | 10 mm to 1000 mm |

| Length | Coil Form or Customized Cut Lengths |

| Finish | Bright, Polished, 2B, BA, Cold Rolled, Hot Rolled |

| Condition | Annealed, Solution Annealed |

| Density | 8.44 g/cm³ |

| Melting Point | 1290 °C – 1350 °C |

| Key Features | Excellent corrosion resistance, High tensile & creep strength, Oxidation resistance up to 1000 °C |

| Applications | Marine applications, Chemical processing, Aerospace, Oil & Gas, Heat exchangers |

Chemical Composition of Inconel 625 Foils

| Element | Content (%) |

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb + Ta) | 3.15 – 4.15 |

| Iron (Fe) | 5.0 max |

| Cobalt (Co) | 1.0 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Aluminum (Al) | 0.40 max |

| Titanium (Ti) | 0.40 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties of Inconel 625 Foils

| Property | Value |

| Tensile Strength | 827 MPa (min) |

| Yield Strength (0.2% Offset) | 414 MPa (min) |

| Elongation | 30% (min) |

| Hardness | 220 HB (max) |

| Density | 8.44 g/cm³ |

| Melting Point | 1290 – 1350 °C |

| Service Temperature | Up to 1000 °C |

Our Global network

Haryana, Sharjah, Doha, Kuwait City, Kolkata, Port-of-Spain, Abu Dhabi, Vung Tau, Nashik, Thane, Ho Chi Minh City, Navi Mumbai, Tehran, Algiers, Ulsan, Coimbatore, Bogota, Jamshedpur, Karachi, Faridabad, Atyrau, Noida, Edmonton, Calgary, Dubai, Cairo, Hyderabad, Hong Kong, Ahvaz, Pimpri-Chinchwad, London, Vadodara, Jakarta, Melbourne, Al Khobar, Aberdeen, New Delhi, Bhopal, Chandigarh, Moscow, Dammam, Mexico City, Kuala Lumpur, Petaling Jaya, New York, Chennai, Santiago, Milan, Los Angeles, Busan, Dallas, Geoje-si, Seoul, Jaipur, La Victoria, Istanbul, Mumbai, Gurgaon, Ankara, Madrid, Houston, Montreal, Singapore, Al Jubail, Pune, Ranchi, Colombo, Howrah, Baroda, Secunderabad, Ernakulam, Surat, Riyadh, Courbevoie, Lagos, Kanpur, Gimhae-si, Lahore, Thiruvananthapuram, Ahmedabad, Manama, Caracas, Muscat, Hanoi, Rio de Janeiro, Visakhapatnam, Bengaluru, Sydney, Bangkok, Jeddah, Chiyoda, Brisbane, Ludhiana, Granada, Rajkot, Toronto, Perth, Indore, Nagpur

Romania, India, Bahrain, Germany, Tibet, Italy, Nigeria, Jordan, Egypt, Argentina, Mongolia, Peru, Costa Rica, Spain, Brazil, Serbia, Portugal, Pakistan, Bangladesh, Thailand, Macau, Slovakia, Belgium, Austria, Lebanon, Ecuador, Sweden, Israel, South Korea, Ghana, Libya, Chile, Hong Kong, Chile, Japan, Poland, Nepal, Gambia, Algeria, Kenya, Trinidad & Tobago,Tunisia, Vietnam, Nigeria, Ukraine, Gabon, United Arab Emirates, South Africa, Estonia, United States, Taiwan, France, Qatar, Morocco, Angola, Bolivia, Bhutan, Switzerland, Bulgaria, Philippines, Sri Lanka, Puerto Rico, China, Canada, Netherlands, Saudi Arabia, United Kingdom, Hungary, Singapore, Ireland, Australia, New Zealand, Yemen, Denmark, Mexico, Lithuania, Czech Republic, Indonesia, Greece, Turkey, Zimbabwe, Croatia, Namibia, Norway, Russia, Iraq, Oman, Kazakhstan, Iran, Azerbaijan, Kuwait, Colombia, Afghanistan, Finland, Belarus, Malaysia, Venezuela